ISOSTATIC GRAPHITE GRAPHILOR®3

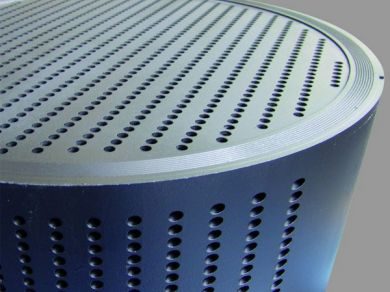

IMPREGNATED GRAPHITE

As a century-old experienced company in manufacturing fine and ultra-fine structured graphite, Mersen has developed its advanced isostatic graphite (grain size of 20 microns): Graphilor®3.

Graphilor® 3 is the only impregnated graphite resulting from the combination between isostatic graphite and a specific resin. It has the highest mechanical properties authorised by TÜV and can withstand extreme temperatures. Mersen offer a range of three Graphilor® 3, based on various impregnations (phenolic, carbon and PTFE) which ensure the imperviousness, the resistance to corrosion and temperature as well as the long-term stability.

3 products

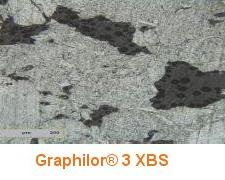

Graphilor®3 XBS (phenolic resin)

Suitable for 80% of applications, available up to 220°C, excellent corrosion resistance.

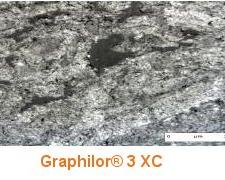

Graphilor®3 XC (carbon resin)

Perfect for very high temperatures up to 430°C.

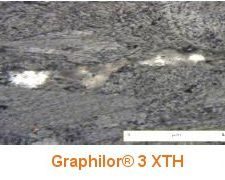

Graphilor®3 XTH (PTFE resin)

High corrosion resistance properties.

Graphilor®3 properties

- Excellent refractory qualities and mechanical properties

- Very good thermal conductivity and temperature resistance

- Non-contaminating

- Exceptional corrosion resistance

TEMPERATURE AND LONG-TERM STABILITY

- Highly cross-linked resin (BS)

- Resin treated at high temperature (C)

- PTFE resin (TH)

Synthetic graphite, the basis of Graphilor

Artificial graphite is manufactured from a mixture graphite, pitch and others. After molding and firing in an inert environment at around 1,000°C, an amorphous and hard intermediate form of carbon is obtained that does not conduct heat or electricity very well.

By heating it to around 3,000°C in the absence of any air, the carbon is purified and crystallized in a mild, greasy form conducting electricity and heat that can withstand chemical corrosion and very high temperatures. This is artificial graphite or electrographite.

Components measuring up to half a cubic meter can be produced. The first graphitisation patent was filed by two engineers working for Société Le Carbone in 1893.

Contact United Kingdom

Durham Lane Industrial Park

Eaglescliffe

TS16 0RH

+44 1642 790 100

Contact United Kingdom

Durham Lane Industrial Park

Eaglescliffe

TS16 0RH

+44 1642 790 100