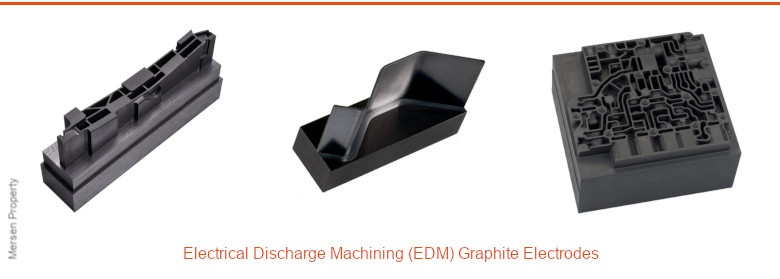

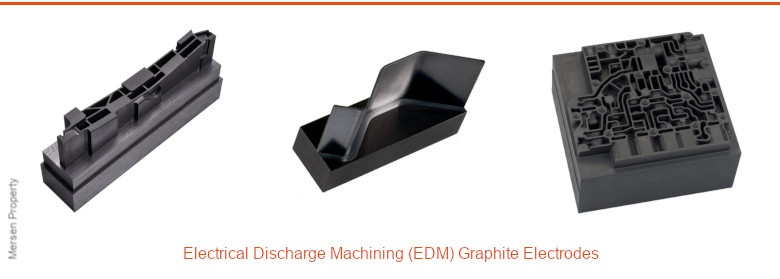

Electrical discharge machining

Mersen, a world leader in the field of iso-static graphite, offers a complete range of ELLOR® graphite grades to suit all EDM applications.

GRAPHITE FOR EDM

ELLOR®: HIGH DENSITY ISO-STATIC GRAPHITE BLOCKS AND BLANKS FOR YOUR EDM ELECTRODES

Graphite has many advantages, making it the most widely used material for EDM electrodes:

- Resistance to thermal shock.

- Low coefficient of thermal expansion and excellent geometric stability.

- Machinability.

- Low wear during sparking.

Mersen is able to recommend the best grade with the best quality/performance ratio based on its customers' unique requirements. Our application experts are at your disposal to provide the support you need in understanding the impact of your machine's configuration and to determine the most efficient parameters.

- ELLOR® +18: A medium density graphite for semi-finishing and roughing operations in the least amount of time and at minimum cost.

- ELLOR®+20: A graphite for both roughing and finishing operations. Ideal for manufacturing plastic moulds.

- ELLOR®+25: The greater density of this grade provides a better surface finish and its mechanical properties enhance the service life of electrodes. A graphite for universal use.

- ELLOR®+30 +40: The surface finish is better and electrode wear is always the lowest.

- ELLOR® +50: The very fine structure of these materials associated with their high density allows them to produce very precise machining details and a remarkable surface finish, whilst reducing electrode wear.

- ELLOR® DS4: The very fine micro-grain structure of this graphite offers unequaled precision and performance.

You can access our EDM web store here: www.mersenshop.uk

GS Teesside office

GS sales office

Boltby Way

Durham Lane Industrial Park

Eaglescliffe

TS16 0RH

Durham Lane Industrial Park

Eaglescliffe

TS16 0RH

T: +44 1642 790 100

GS Carbon & Felt Products Holytown office

GS sales office

15/11/2019 - 4.36 MB